|

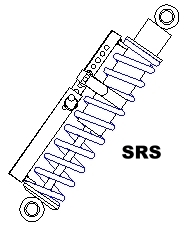

Featuring the first to market Shock Relief System (SRS). It is just that, a combined shock and spring relief. It transfers the weight normally applied to your front shocks and springs allowing them to rest at full extension during storage. There are multiple lifting devices for the rear of your sled but now there is one to relieve the shock pressure in the front. Everyone complains about the handling of there sled, well for most of the year when your sled is in storage or sitting idle for any period of time, your shocks are resting with all the weight over them. Anywhere you read about proper sled storage it will mention to lift the rear of the sled to unload the pressure from the shocks and springs. It will also mention that you should do the same for the front. Most don't mess with the front because there is no easy and quick and inexpensive way to do it, until now. The SRS is that product. If you buy jack stands for storage to save the rear shocks and springs then you need the SRS to take the load off the front. Plus when you lift the back of your sled more weight gets transferred to your front shocks and springs. This weight is sitting over the front for 8 to 9 months a year! (We wish it were a lot less!) [Read SnowTech Feedback - Sept 2000] The SRS,

unlike a block of wood under your bellypan, can still be

left in place while you move your sled around. You can

also keep the ski roller dollies under your skis during

storage. Go out into your garage or trailer and lift up

the front of your sled, I bet you will lift 3-5 inches

before your skis even move. Some sleds a lot more. That

will give you some indication as to how much fading your

shocks are going through during sitting times. Remember

your shocks natural position is to be fully extended.

With the SRS you will not only reduce fade, but the

longevity of the shocks and constant compression on the

springs too!

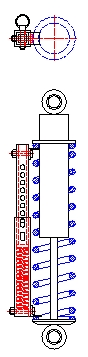

The SRS

works best on non-progressive spring designs (shown at

upper left). Meaning the ones that have consistent

spacing (pitch) between coils. The reason is that the SRS

attaches to the uppermost and lowermost coil on the shock

spring. If the spring is progressive then the coils tend

to get closer and the SRS would have to be placed on the

highest coil available. It will still work however, but

due to the small gap in the springs that are tightly

wound at one end it will compress slightly more than

those with a consistent pitch. It should still work fine

for most applications. The SRS will only fit into gaps

larger than 1/8".

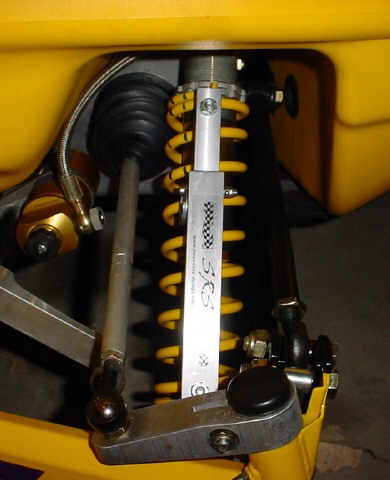

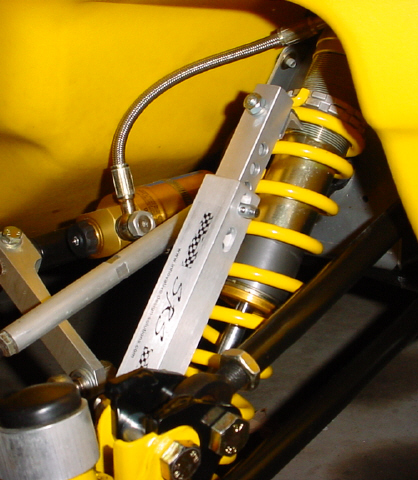

The SRS will work on ATV coil over shocks as well. On ATVs before you order, lift the front end and measure the total uncompressed distance from top spring to bottom (if progressive then measure to the nearest coil with a minimum coil gap of 1/8"). Some ATV might have a distance greater than 10.75 inches total height.

$49/pair - Fits (2) shocks1 $29 ea. - Fits (1) shock1 1Shipping will be billed at actual cost. Click photo for a larger view |

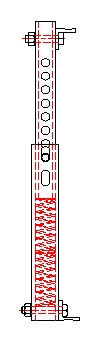

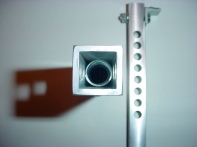

Above;

Typical snowmobile front spring application. (Works with

shocks facing either direction.) Features: 7.25" - 10.75" total height adjustment 1/4" & 1/2" increment adjustment Zinc plated ball lock pin Machined grooves in the brackets to fit the profile of the springs. Aluminum Sq. Tubing construction Anodized in red, blue, or clear. Steel bolt-on angle brackets that maximize strength and ability to fit into tight spring spaces. Aluminum particle coated brackets with black Neoprene rubber foam adhesive strips to protect the springs. Spring assist to help keep the SRS in place during install & when unloading the pressure from the springs. Adjustment

slotted holes use the spring assist to allow upward

pressure on the springs when moving the sled, so they

don't fall out of place. 1) Place the springs into the larger tube.

2) Compress the SRS by pulling the smaller tube down into the larger tube. If you need less height, remove (1) one of the springs in the larger tube. Both springs should work on most. 3) Place the SRS into the furthest spring spacing possible. If you have threaded shocks turn shocks to get the farthest position facing the outside of the sled. (always release spring preload for longevity of your springs) 4) Make SURE the SRS is parallel with the shock and the machined grooves are in line with the spring. Position the smaller tubing on the shock side the larger tubing on the rod side or whatever works best for your sled. 5)The internal springs should hold it in place. Lift the front of the sled and have someone push the lock pin in the adjustment hole that gives you the greatest height. (If the spring gap is too small to fit the brackets, then lift the sled first, then put the SRS in place.) 6) Repeat for both sides. 7) Release

the weight back to the front of the sled and the SRS

should be holding the front end of sled up strong and

steady! |